-

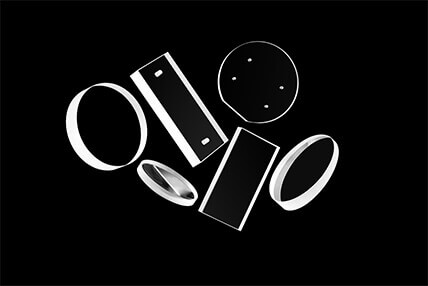

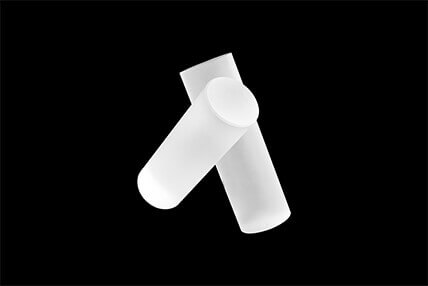

Lithium Fluoride(liF) Lenses

Lithium Fluoride(liF) LensesProxy Crystals offers lithium fluoride lens blanks, plano-convex lenses, prisms and aspheres. The process used is a combination of PITECH polishing and DTM.

Lenses are available up to 4″. -

Lithium fluoride(LiF) oriented materials

Lithium fluoride(LiF) oriented materialsLiF has excellent optical properties, especially in the deep ultraviolet band. With the development of deep ultraviolet technology in recent years, lithium fluoride crystals have received more and more attention for their high transmittance and short cut-off wavelength in the deep ultraviolet band. Lithium fluoride is a tetragonal crystal system, and the crystals can be grown as single polycrystalline blocks or single crystals with directional growth. Therefore, there is a difference between single crystal and polycrystalline lithium fluoride. Polycrystals are mostly used as protective windows; single crystals can be used as lenses, prisms and viewing windows. The most common orientation of crystals is 100, but 111 is also used.

-

Lithium fluoride(LiF) coating material

Lithium fluoride(LiF) coating materialWe provide lithium fluoride coating particle materials and coating target materials. Mainly used for OLED electrode coating and screen coating layers, the size can be 1-3 or 3-6 mm; also can be 0.1-1 mm; the purity is above 4N, review REACH and ROHS standards. Lithium fluoride coating target is mainly D40-50*50-60mm crystal material, the effect and quality is more

-

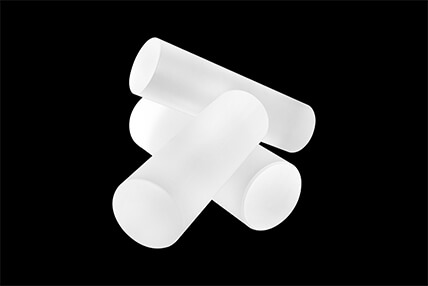

Magnesium fluoride(MgF2) polycrystalline material

Magnesium fluoride(MgF2) polycrystalline materialPolycrystalline magnesium fluoride can be infrared polycrystalline or ultraviolet polycrystalline material, often used for protection windows or analytical instruments to transmit the signal of the lens, or coating target material. However, polycrystalline magnesium fluoride cannot be used as a lens because of its birefringent properties, which will produce two or more images when focused.

-

Magnesium fluoride(MgF2) wave plate

Magnesium fluoride(MgF2) wave plateMagnesium fluoride is often used as achromatic bonded waveplates because of its birefringence property. Our magnesium fluoride is made of 4N grade raw material, specific growth and rejection process, and ultra-precise cutting and orientation process, which can reduce the difficulty of precision control in the manufacturing process of your wave sheet and the precision of phase delay in use more effectively.

-

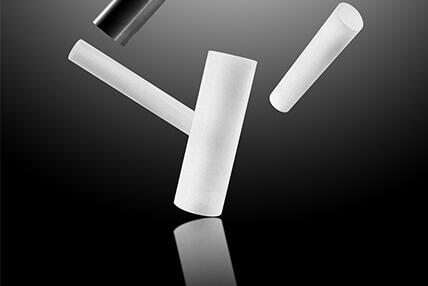

Low stress magnesium fluoride(MgF2) bar

Low stress magnesium fluoride(MgF2) barGrain boundary stress is the stress acting on the grain boundary. On the grain boundary surface, the atomic arrangement transitions from one orientation to another, so the atomic arrangement at the grain boundary is in a transition state. The contact interface between the grain and the grain is called the grain boundary. Low stress magnesium fluoride refers to the maximum stress less than 15NM for magnesium fluoride with length greater than 40mm or less than 3NM for 2mm thickness. The low stress is directly related to the crystal growth process, annealing process, and post-processing and treatment.

- Crystal Material

- Lanthanum tribromide LaBr3

- Calcium fluoride (CaF2)

- Barium fluoride(BaF2)

- Magnesium fluoride (MgF2)

- Lithium fluoride(LiF)

- Silicon material(Si)

- Germanium material(Ge)

- NaI:TI

- Lithium Niobate

- Zinc Selenide(ZnSe)

- Zinc Sulfide(ZnS)

- Sapphire

- Quartz

- Laser Lenses

- Laser output Coupler

- Laser Protection Window

- Beam Combine

- Laser scanning mirror

- Laser Mirror

- Focusing Lens

- Laser Window